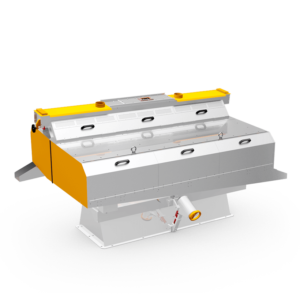

Underrunner disk sheller type USG

Efficient hulling of ancient grains and pulses

High performance with low operating costs: the hulling principle of this machine allows for the best possible hulling of all ancient grain varieties and pulses with a high protein content.

Two hulling stones in a robust hulling bed

In the cast iron hulling bed of the underrunner are two hulling stones which are coated with a resilient corundum-emery compound. Between the stones – the upper one is fixed while the lower one moves – is where the grain is processed. The intensity of the hulling effect can be regulated using the robust distance adjustment mechanism for the hulling gap.

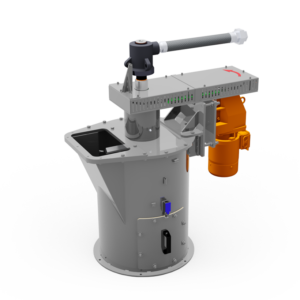

Flexibly adjustable inlet pipe

The performance of the machine is adjusted via an individually adjustable inlet pipe. The rapid flow of the hulling mixture as well as an extremely gentle processing of the hulled product are ensured by two outlets positioned on opposite sides.

At a glance

-

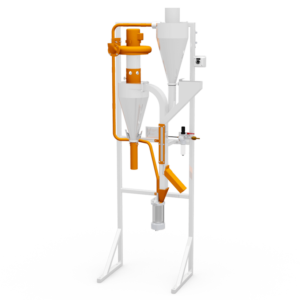

Optimal for use in spelt hulling installations, soya mills, and installations for extracting protein from peas and fava beans

-

High performance with low wear and hence low running costs

-

Special stone coating guarantees a long service life and maximum hulling efficiency

-

Suitable for the following grains: Spelt, einkorn, emmer, soya, peas, lentils, lupins, buckwheat, millet, legumes

But that's not all the underrunner disk sheller can do for you

The machine can also be used for the granulation or milling of special products which require a special geometry or surface structure – such as bulgur.

Tobias and Florian Streckel

Further questions?

Feel free to ask us any questions you may have. Simply send us an