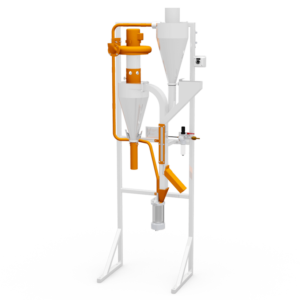

Laboratory stone huller type LU-200

The stone huller for laboratory applications

This standard machine for spelt hulling impresses with a wide range of possible applications, and supplies representative results in the laboratory.

The underrunner's little brother

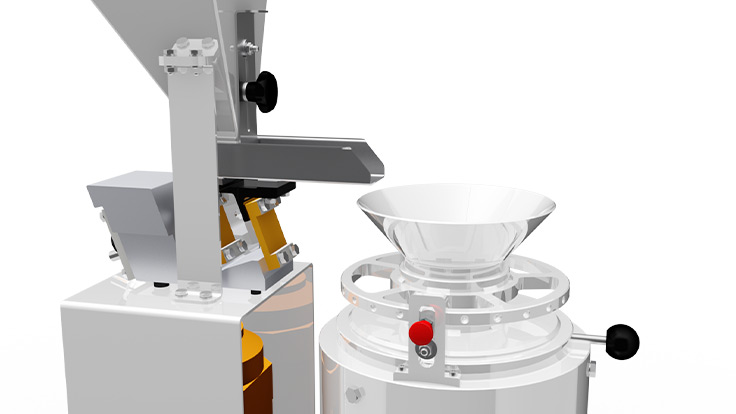

The grain is fed in via a vibrating trough and processed between the stone coatings made of a robust corundum-emery mixture. The individual degree of hulling depends on the slightly adjustable width of the hulling gap. After the process, a mixture of hulled and unhulled kernels and hulls is created, which then needs to be separated manually or mechanically.

An important laboratory all-rounder

Thanks to the exact recording of the hulling process, the laboratory stone huller allows direct predictions to be made regarding the hullability on an industrial scale. At up to one kilogram, the sample size is sufficiently large to precisely determine the falling number. Furthermore, thanks to a variable rotational speed and feed-in, the laboratory stone huller supplies representative results with regard to degree of hulling and other significant product properties in the industrial process.

At a glance

-

Laboratory version of the underruner

-

Standard machine for hulling spelt in Germany and Europe

-

Exact milling gap setting for comparable hulling results

-

Representative results in the laboratory

-

Variable rotational speed and feed-in

-

Collection tank for hulled mixture secured with safety switch

-

Suitable for the following grains: Spelt, emmer, einkorn, legumes, buckwheat, millet

But that's not all the laboratory stone huller can do for you

The laboratory stone huller also provides representative sample sizes for seed cultivation, because the processing can take place so rapidly that the kernel properties of the grain are not negatively influenced.

Technical data

-

Weight

65 kg

-

Motor

0.25 kW

-

Dimensions

575 x 319 x 739

Download data sheet

Tobias and Florian Streckel

Further questions?

Feel free to ask us any questions you may have. Simply send us an