Groat cutter type Krone 2

The evolution of a precise classic

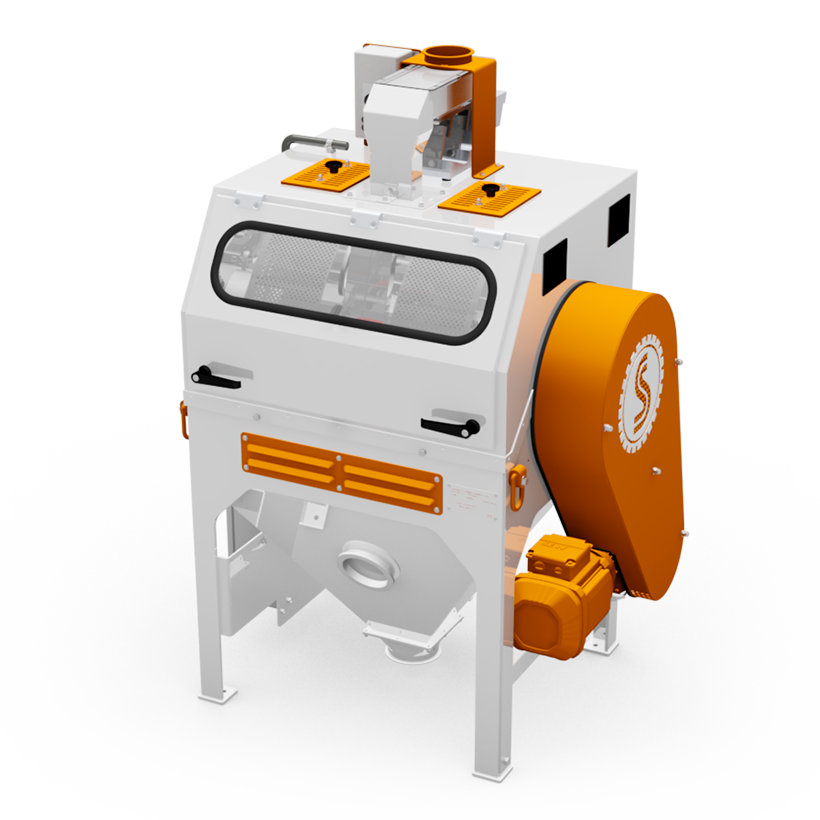

This machine is used to manufacture cut grain kernels that are sliced perpendicular to the longitudinal axis, called steel cut groats. The new version Krone 2 impresses with exceeding cleanliness and improved performance.

Maximum throughput and efficient operation

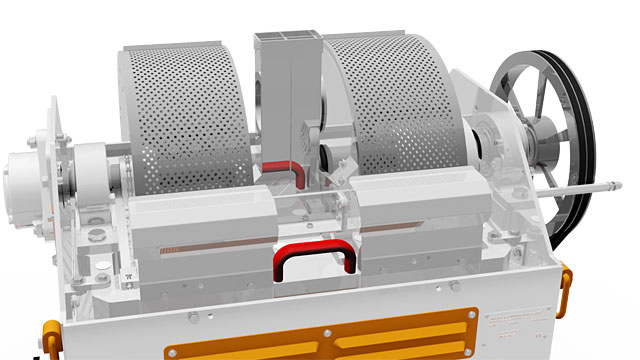

Via an adjustable vibrating trough, the grain is fed into the machine. Subsequently, the cutting process takes place with the aid of two perforated drums and blade cages attached to a swivelling frame. Rotating toothed rollers ensure that the over 6,500 holes in the drum are constantly being cleaned.

Experience the next generation

Unlike its predecessor, the new machine does not have a closed housing at the base. The discharge hopper is steeper and the groat cutter can be connected to an intensive extraction system via a specially designed aspiration duct and throttle valve. Furthermore, the space requirements were significantly reduced and maintenance simplified. For example, it is no longer necessary to dismantle the main bearing when replacing the drum.

Easy sharpening of blades

Custom adjustment of the blade spacing makes it possible to sharpen the blades multiple times. It is also possible to react flexibly to quality fluctuations in the harvest. The blade cages can be rotated by 180 degrees for inspections and maintenance without having to remove the upper section of the machine.

At a glance

-

The high-performance new generation for the optimal production of steel cut groats

-

Two drums with 29 rows of perforations and a total of over 6,500 holes per drum

-

Aspiratable interior with configurable supply air regulation

-

Less surfaces for deposits in the interior

-

Improved inlet contour and higher-performance vibrating feed

-

Easier maintenance, inspection, and cleaning thanks to external main bearing and assembly jib

-

Open housing for better hygiene and cleanliness

-

Compact and space-saving

-

Suitable for the following grains: Oats, spelt, barley, rye, wheat

But that's not all the groat cutter can do for you

Do you already have a number of machines belonging to the previous model? Please get in touch with us to enquire about a performance upgrade for your Krone groat cutter to the version Krone 2. By upgrading the entire cutting mechanism incl. drums, you will not only increase the performance of your old Krone groat cutter, but also ensure homogeneity for replacement parts between your existing machines and the new model Krone 2.

Technical data

-

Weight

418 kg

418 kg -

Motor

1.1 kW

1.1 kW -

Dimensions

1074 x 781 x 1461

1074 x 781 x 1461

Download data sheet

Tobias and Florian Streckel

Further questions?

Feel free to ask us any questions you may have. Simply send us an