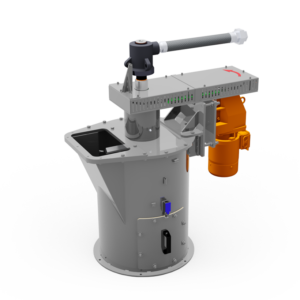

Feeding roll type SPA

Quality across the entire breadth

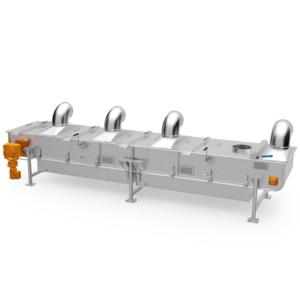

Capitalise on the full potential: the feeding roll distributes your product over the entire working width – for an even and continuous hydrothermal process.

How it works. Because it works.

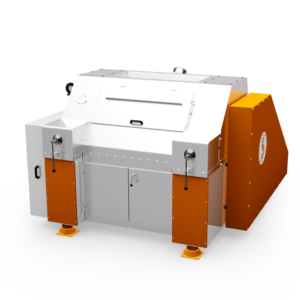

The feeding roll forms the interface between hydrothermal processes and subsequent product finishing, such as flaking. Operated with a frequency inverter, the feeding roller and the custom-configurable feed gate work together to ensure even distribution of the product over the entire working width. Apart from the temperature, the retention time also has an influence on the later final product. Hence, the feeding roll is not only a distribution device, but also controls the timing for the hydrothermal process. Naturally, it is made completely of stainless steel.

Blasting away steam

Using aspiration, vapours generated in the process but which are not desired in the final product are extracted via suction. The aspiration hood is outfitted with quick-release fasteners, which allow it to be removed easily. This ensures good and quick accessibility when the machine needs to be cleaned.

At a glance

-

Aspiration hood for easy cleaning

-

Homogeneous distribution

-

Inspection hatch for visual checks

-

High process reliability

-

Suitable for the following grains: Oat kernels and steel cut groats, maize, wheat, barley, buckwheat, millet, rice

But that's not all the feeding roll can do for you

Optionally, the feeding roll can also be outfitted with an automatic feed gate.

Technical data

-

Gewicht

96 kg

134 kg

152 kg -

Antrieb

0.37 kW

0.37 kW

0.37 kW -

Maße

1164 x 511 x 350

1340 x 511 x 350

1548x511x350

Download data sheet

Tobias and Florian Streckel

Further questions?

Feel free to ask us any questions you may have. Simply send us an