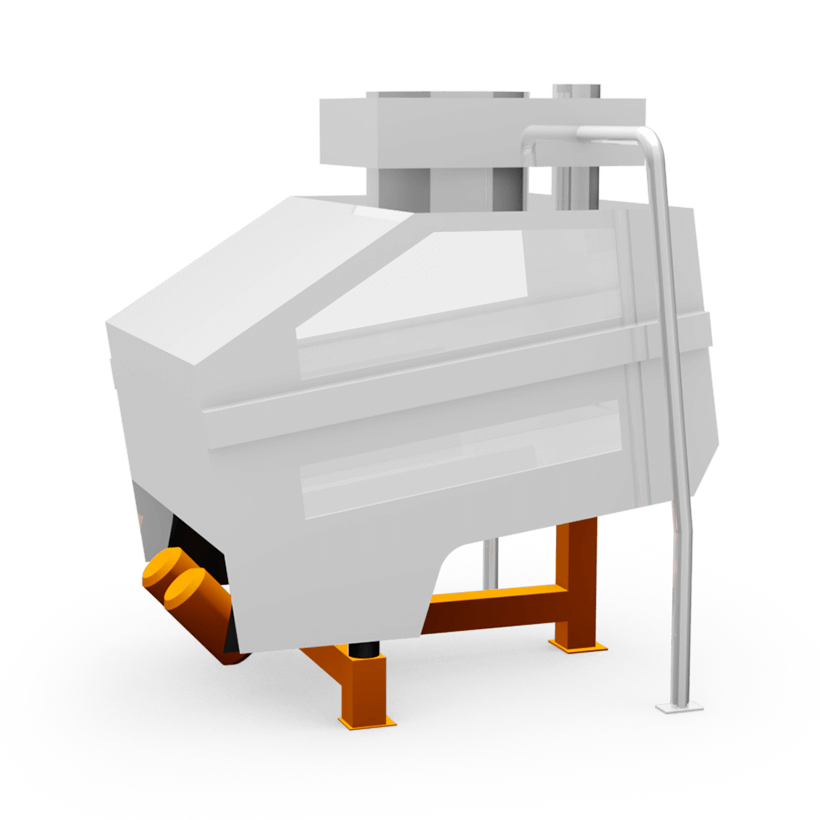

Destoner type MTSC

End of the line for heavy foreign objects

A destoner is an essential component in every classic grain cleaning process. It operates using a suction principle and ensures reliable further processing.

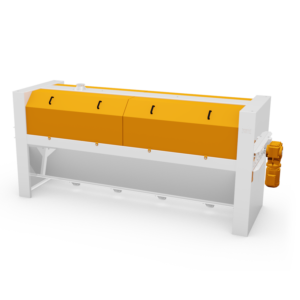

Destoner type MTSC 120 – 120

The thorough double-decker

Depending on the model, up to two vibration motors drive the compact machine, through which the product is evenly distributed in the airtight working chamber. On the first level, a pre-selection takes place: Using streams of air and oscillating movements, light particles are separated from heavy ones. The heavy particles travel to a second separating table on which the final sorting takes place. Finally, the clean grain as well as the stones are transported out via rubber valves.

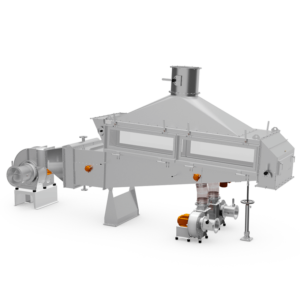

Destoner type MTSC 65 – 120

Stable air conditions. Meticulous sorting.

In order to ensure that every single little stone is sorted out, stable air conditions are required in the working chamber of the machine. Hence, our compact destoner is supplied with its own fan which rules out any air fluctuations.

At a glance

-

Self-cleaning via plastic cubes in the decks

-

Maximum sorting quality via double deck technology

-

Inspection window made of shatterproof Makrolon; inspection and cleaning openings with rubber covers

-

Suitable for the following grains: Rice, oats, millet, buckwheat, peas, barley

But that's not all the destoner can do for you

Depending on requirements, the destoner is available in two sizes. It integrates seamlessly into your production chain and not only cleans the product, but also protects downstream machines.

Technical data

-

Weight

480 kg

624 kg -

Motor

0.3 kW

2 x 0.3 kW -

Dimensions

1722 x 986 x 2105

1580 x 1526 x 1805

Download data sheet

Tobias and Florian Streckel

Further questions?

Feel free to ask us any questions you may have. Simply send us an