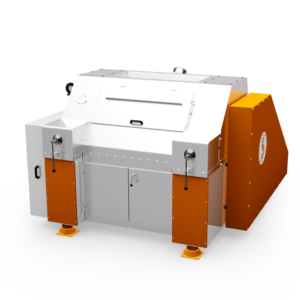

Counter current coarse sifter type FSW

All-round performer

The big finale of the cleaning process: This is where already hulled grains are cleaned once again using air. And you have everything fully under control.

Counter current coarse sifter type FWS 500

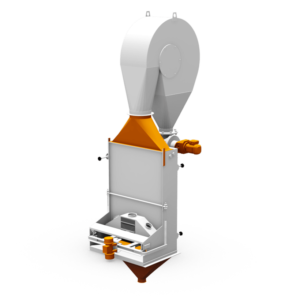

Gone with the wind

Residual hulls, flour, and dust don’t stand a chance with this addition to your system. At right angles, the product falls through the centrally positioned inlet onto the height-adjustable scatter sphere and is distributed over the entire area. A circumferential inspection window allows for visual inspection. Unwanted components are effectively extracted via suction against the flow of product.

Counter current coarse sifter type FWS 300

Configuration is key

Adjusting the scatter sphere determines the product flow on the inside. Furthermore, varying the throttle valve setting allows the airflow to be adjusted to the respective requirements.

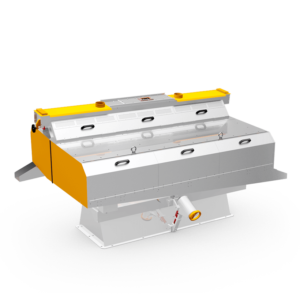

At a glance

-

High-performance aspiration in small spaces

-

Visual inspection via circumferential inspection window

-

Can also be used for cooling during grinding phases

-

Available in version made completely of stainless steel upon request

-

Suitable for the following grains: Oats, spelt, barley, rye, wheat etc.

But that's not all the counter current coarse sifter can do for you

Should the installation height be insufficient, we can offer you a customised aspiration solution.

Tobias and Florian Streckel

Further questions?

Feel free to ask us any questions you may have. Simply send us an