Process

Cornflake manufacturing

The manufacturing process

-

Hydrothermal treatment

-

Pre-drying

-

Flaking

-

Roasting

-

Cooling

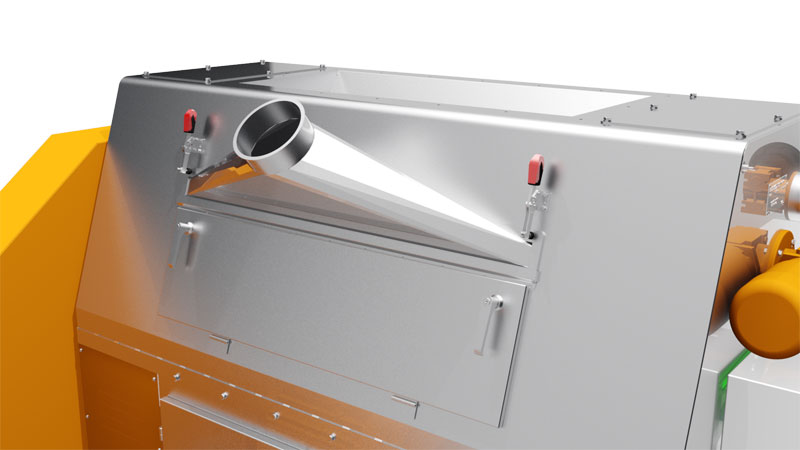

Hydrothermal treatment

The product is – usually with the addition of other ingredients – steamed on the interior of the cooker, thereby making it flexible for further processing on the roller mill. The rotation of the cooker during the entire cooking process ensures a homogeneous result.

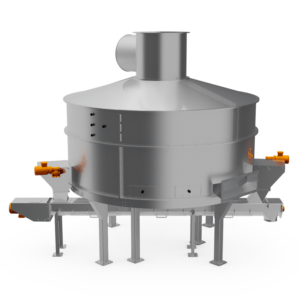

Plate dryer type TD 3000

Pre-drying

The cooked maize grits fall onto the perforated floor, after which they are mixed with the aid of 4 mixing arms, and evenly dried. The drying is performed via a vertical flow of air in the machine.

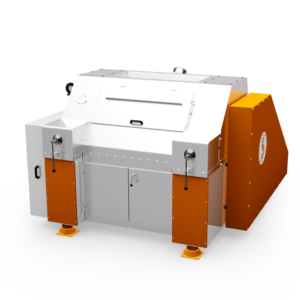

Flaking roller mill type FWS

Flaking

After drying, the maize grits are rolled to make flakes. For this purpose, the product is distributed over the entire width of the rollers. The high hydraulic compacting pressure and a precise roller setting create cornflakes with a consistently high quality.

Roasting

The still soft and flexible cornflakes are dried in the roaster with heat. This is where the cornflakes get their typical “crunch” through the formation of blisters.

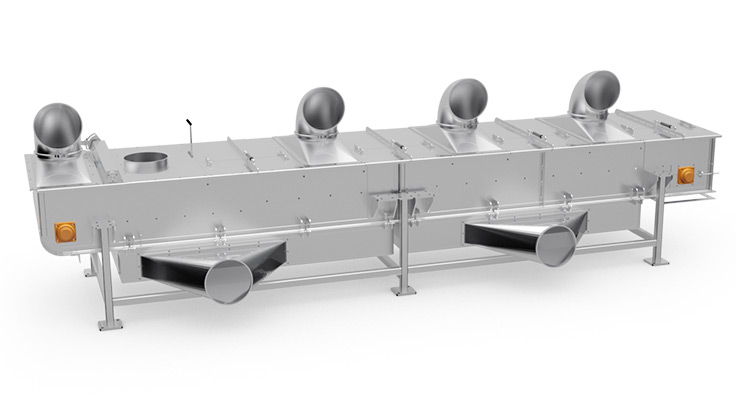

Cooling belt with air blow-in box 5m

Cooling

The cooling of the roasted cornflakes takes place via cold air that is blown in while the product is transported gently on the hatch conveyor from the inlet to the outlet.