100 Years of Streckel & Schrader

Company History

1923 to 1939

The two engineers Franz Streckel and Karl Schrader met at Maschinenfabrik Eisen AG, which later became Kampnagel AG. While F. Streckel was in charge of the international business, K. Schrader was responsible for tasks within the company. In 1923, the two mill technology specialists decided to set up their own company dedicated to selling rice mills. In spite of the difficult economic situation, with hyperinflation, mass unemployment and civil unrest, they were able to build and establish the company. On December 1, 1924, they moved into a property on Hinschenfelder Strasse in Hamburg-Wandsbek, which continues to be the company’s headquarters today. Franz Streckel’s son Karl Bruno was 25 years old when he joined the company in 1925. He had studied engineering in Stuttgart.

When the Great Depression hit in the late 1920s, many companies in Germany collapsed. However, food processing machinery was still needed, and this allowed Streckel & Schrader to survive this period relatively unscathed.

In the years that followed, it acquired new customers abroad and the number of employees increased. By 1932, the company was able to manufacture all the parts of a rice mill on its own, and the company also began building entire oat mills. Business flourished. However, working with customers in Indonesia or South America was difficult because of its dependence on trading companies. Streckel & Schrader had to compete with strong rivals – Huckauf & Bülle, Eisenwerk AG, Körber & Naumann, and F. H. Schule.

1939 to 1945

World War II also hit Streckel & Schrader hard. Important foreign markets collapsed, many employees were drafted into the Wehrmacht, and submarine covers were manufactured in the company’s halls. In 1941, founder Franz Streckel, who had become a close advisor to many of the company’s customers, died at the age of 72.

From then on, his son Karl ran the company together with Karl Schrader. The premises of the company were spared from damage by bombs. Other businesses, however, were badly affected, including grain processing factories. Streckel & Schrader was inundated with repair orders.

1945 to 1967

When World War II ended in May 1945, Streckel & Schrader suffered from the loss of its business relationships abroad. During this time of uncertainty, Karl Schrader died, leaving Karl Streckel alone at the helm of the company. He converted the company into a limited partnership (KG) and was solely responsible from then on.

The Deutschmark was introduced in 1948. With the currency reform, the economic situation slowly began to improve. Karl Streckel re-established his business contacts and travelled all over Europe to visit his customers. By the end of the 1950s, he was able to organise trips to Burma, Pakistan and other East Asian countries with representatives of the trading companies. He won over customers with quality, excellent service and very well-trained employees. Things were looking up.

1967 to 2000

Joachim Streckel, the third generation of the family, joined the company in 1967. Before joining the company at the age of 23, he had completed a business apprenticeship. On 1 July 1973, Streckel & Schrader celebrated its 50th anniversary. One of the first major changes Joachim Streckel made to the family-owned company was to stop working with trading companies. This enabled him to expand the sales territory and also develop the business in South America and Australia. At the time of his death in 1984, at the age of 84, Karl Streckel had no doubt that the family business was in good hands. Joachim Streckel decided to subcontract parts that required little effort and expertise. He also had machines for simple production processes built by other companies. This allowed Streckel & Schrader’s highly skilled employees to focus more on developing and manufacturing components which required a great deal of expertise. The groundwork for mass production had been laid. This strategy enabled Joachim Streckel to significantly increase efficiency and profitability over the next 20 years.

2000 to 2023

In the new millennium, Streckel & Schrader’s core sales market was also initially outside Europe – Australia, New Zealand, South America and China. Today, the company focuses on the production of equipment for processing oats and spelt. These include machines for cleaning, sorting and hulling grain, as well as a groat cutter, for which Streckel & Schrader is the world market leader. The product range also includes systems for hyperthermal processes, machines for flaking and special-purpose machines.

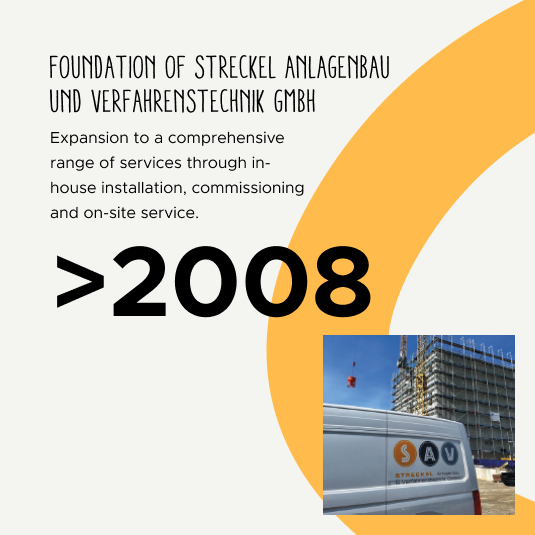

In 2004, at the age of 28, Tobias Streckel took over sales and consultancy for system planning, and three years later he became managing director of Streckel & Schrader. In 2008, the business graduate founded Streckel Anlagenbau und Verfahrenstechnik (SAV) to complement the Streckel & Schrader portfolio and to better plan and execute the installation and maintenance of Streckel & Schrader systems. From then on, Streckel & Schrader took on an increasing number of large-scale projects. In order to cope with the ever-increasing volume of orders, the production areas were expanded in 2011 and the office workstations were completely modernised and extended.

Fortunately, Florian Streckel, Joachim Streckel’s second son, also decided to join the family business in 2013 to help drive growth and sustainable development. After studying business administration, he worked for PricewaterhouseCoopers AG before also joining Streckel & Schrader at the age of 28.

On 1 January 2014, Streckel & Schrader KG became Streckel & Schrader GmbH & Co. KG, and the company is now fully owned by the Streckel family.

In 2021, an opportunity to acquire another Streckel & Schrader production site arose. The two brothers bought a suitable production hall in Lutherstadt Wittenberg and thus created sustainable prospects for the future in not one, but two respects. In 2022, the production hall was extensively renovated and outfitted with a large-scale solar installation. Over the past decade, Streckel & Schrader has increasingly and single-handedly been responsible for the realisation of major projects, from the conception and engineering to the implementation, both in Germany and abroad.