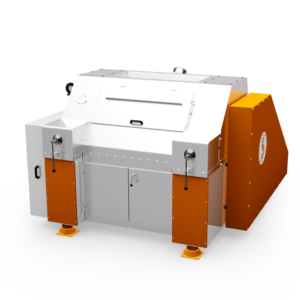

Impact dehuller type FKS 560

High flexibility with excellent degree of hulling

The impact dehuller type FKS 560 is a flexible classic that guarantees a high degree of hulling with low breakage.

Tried-and-tested procedure with good output

The success of the impact dehuller type FKS 560 is due to its classic, tried-and-tested impact process: The cleaned, de-stoned product to be hulled is fed into the impeller via an inlet, where it is evenly scattered via a distribution mechanism. Finally, the grain is hurled at the impact ring in a targeted fashion, which is made of steel or rubber depending on the type. The hulling performance can be controlled via the steplessly adjustable inlet pipe, and naturally the rotational speed of the impeller can also be tuned to the product.

Gentle hulling of sensitive grains

Particularly for the confectionery market, it is essential to hull grains and seeds without them breaking. Thanks to the gentle method, the impact dehuller type FKS 560 is ideal for this purpose. The machine is suitable for a variety of uses and can be employed both as a primary huller or a post-huller for products that are difficult to hull, such as small oat varieties.

At a glance

-

High degree of hulling with low breakage

-

Gentle processing thanks to low rotational speeds and low drive power

-

Low operating costs

-

Can be used as primary or post-huller

-

Suitable for the following grains: Oats, sunflower seeds, millet (post-hulling), spelt (post-hulling), hemp seeds (special model)

But that's not all the impact dehuller type FKS 560 can do for you

The impact dehuller is also available in a more powerful version, such as for sunflower seed. We also supply a special version designed specifically for the complex hulling of hemp seeds.

Technical data

-

Gewicht

255 kg

-

Antrieb

3 kW

-

Maße

1016 x 840 x 1283

Download data sheet

Tobias and Florian Streckel

Further questions?

Feel free to ask us any questions you may have. Simply send us an